California Department of Transportation: Maintenance Life Cycle Cost Analysis

The Client

The California DOT (Caltrans) Division of Maintenance is responsible for maintaining 15,200 centerline miles of highway and 12,312 state highway bridges, as well as maintaining 350,000 acres of right of way. As the third largest US state by area, Caltrans maintenance teams also have to contend with a variety of geographic and weather-related conditions, from mountains and heavy snow in the east to deserts and intense heat in the south.

The Challenge

As transportation assets age, the cost to maintain them grows – often at an increasing rate. With the prospect of stagnant and decreasing budgets, Caltrans needs a better way to anticipate growing maintenance demand and reduce worker exposure without sacrificing system performance. The agency wants to use its maintenance funds more effectively, thereby performing the right maintenance in the right place at the right time.

The Solution

DMG worked with Caltrans to develop a life cycle cost analysis (LCCA) toolset that can lower its maintenance budget and reduce worker exposure during maintenance activities. Unlike traditional construction and maintenance decisions that simply consider initial construction costs, LCCA also takes into account an asset’s ongoing maintenance expenses and disposal costs. When an asset’s maintenance strategy utilizes LCCA effectively, overall maintenance cost and worker exposure can decrease while system performance is maintained or improved.

The project team created three tools to address the project goals. First, the Integrated Maintenance

Management System (IMMS) expense data tool will help Caltrans determine total maintenance cost by asset. This tool receives maintenance expenditure, maintenance labor, and total inventory data inputs and allocates them across appropriate IMMS assets. It also allows the user to report the IMMS maintenance funding and time spent maintaining all assets each year. The tool contains two reporting tabs: one that displays a summary of all IMMS data for the past five fiscal years and one that allows the user to filter the IMMS data by fiscal year, district, county, route, and/or climate region.

Second, the overall maintenance budget tool provides a summary based on all maintenance expenditures. It combines the maintenance contract and major maintenance expenditures with the IMMS data. This tool display maintenance expenditures and labor hours attributed to each asset type for the past five fiscal years. It also shows inventory counts and LOS scores, when available. The tool can also filter all results by district.

Lastly, the impact attenuator LCCA tool compares maintenance expenditures within different types of the same asset to support LCCA during asset installation, maintenance, and replacement decisions. Users can generate reports that show attenuator maintenance expenses and inventory counts at the district, county, and route levels. To optimize this tool for future use, Caltrans will assign a unique inventory number to each attenuator. By connecting cost and labor data to specific assets, Caltrans will then know the average cost for each attenuator type and be able to act on that information.

The Results

Caltrans‘ responsibility to maintain its system is enduring, even when budgets are uncertain. This LCCA toolset allow Caltrans to make better-informed, strategic maintenance decisions. By applying LCCA across its assets, Caltrans will be better prepared to meet its goals of lower maintenance expenditures, reduced worker exposure, and optimized system performance.

California Department of Transportation: Maintenance Life Cycle Cost Analysis

The Client

The California DOT (Caltrans) Division of Maintenance is responsible for maintaining 15,200 centerline miles of highway and 12,312 state highway bridges, as well as maintaining 350,000 acres of right of way. As the third largest US state by area, Caltrans maintenance teams also have to contend with a variety of geographic and weather-related conditions, from mountains and heavy snow in the east to deserts and intense heat in the south.

The Challenge

As transportation assets age, the cost to maintain them grows – often at an increasing rate. With the prospect of stagnant and decreasing budgets, Caltrans needs a better way to anticipate growing maintenance demand and reduce worker exposure without sacrificing system performance. The agency wants to use its maintenance funds more effectively, thereby performing the right maintenance in the right place at the right time.

The Solution

DMG worked with Caltrans to develop a life cycle cost analysis (LCCA) toolset that can lower its maintenance budget and reduce worker exposure during maintenance activities. Unlike traditional construction and maintenance decisions that simply consider initial construction costs, LCCA also takes into account an asset’s ongoing maintenance expenses and disposal costs. When an asset’s maintenance strategy utilizes LCCA effectively, overall maintenance cost and worker exposure can decrease while system performance is maintained or improved.

The project team created three tools to address the project goals. First, the Integrated Maintenance

Management System (IMMS) expense data tool will help Caltrans determine total maintenance cost by asset. This tool receives maintenance expenditure, maintenance labor, and total inventory data inputs and allocates them across appropriate IMMS assets. It also allows the user to report the IMMS maintenance funding and time spent maintaining all assets each year. The tool contains two reporting tabs: one that displays a summary of all IMMS data for the past five fiscal years and one that allows the user to filter the IMMS data by fiscal year, district, county, route, and/or climate region.

Second, the overall maintenance budget tool provides a summary based on all maintenance expenditures. It combines the maintenance contract and major maintenance expenditures with the IMMS data. This tool display maintenance expenditures and labor hours attributed to each asset type for the past five fiscal years. It also shows inventory counts and LOS scores, when available. The tool can also filter all results by district.

Lastly, the impact attenuator LCCA tool compares maintenance expenditures within different types of the same asset to support LCCA during asset installation, maintenance, and replacement decisions. Users can generate reports that show attenuator maintenance expenses and inventory counts at the district, county, and route levels. To optimize this tool for future use, Caltrans will assign a unique inventory number to each attenuator. By connecting cost and labor data to specific assets, Caltrans will then know the average cost for each attenuator type and be able to act on that information.

The Results

Caltrans‘ responsibility to maintain its system is enduring, even when budgets are uncertain. This LCCA toolset allow Caltrans to make better-informed, strategic maintenance decisions. By applying LCCA across its assets, Caltrans will be better prepared to meet its goals of lower maintenance expenditures, reduced worker exposure, and optimized system performance.

Mississippi Department of Transportation: Maintenance Management Consulting Services

The Client

The Mississippi DOT (MDOT) is responsible for providing a safe intermodal transportation network that is

planned, designed, constructed and maintained in an effective, cost efficient, and environmentally sensitive manner. In particular, MDOT’s Maintenance Division administers the varied programs necessary for the preservation, maintenance and safety of approximately 10,000 miles of state and federal highways.

The Challenge

In the mid-2000s, MDOT managed its maintenance and operations (M&O) needs with a legacy management system based on pass-fail ratings. MDOT wanted a more performance-based maintenance management approach that would allow it to spend time and money on the right things at the right time for the right reasons.

The Solution

Dye Management Group helped the Mississippi DOT review its maintenance business practices and processes, and prepare a plan for implementing a level-of-service (LOS)-based condition rating system and an associated condition-based activity budgeting process. The plan, along with other recommended improvements, defined the DOT’s future, or to-be, maintenance management business processes. Our team updated MDOT’s Maintenance Field Operations Manual to reflect the new, department-approved, performance-based business practices and processes. In addition, we prepared requirements and an implementation strategy for a new maintenance management system (MMS) that would enable and support the to-be maintenance business processes.

Through follow-on work, we assisted in the implementation of a newly developed maintenance quality assurance (MQA) program, performed customer surveys, and led focus groups. Our team also assisted with the procurement and implementation of a new MMS – called Accountability in MDOT Maintenance Operations (AMMO) – based on newly developed requirements, and provided project management support and organizational change management.

Most recently, DMG assisted the Mississippi DOT with a post-implementation review of the AMMO application. We conducted a series of group interviews, workshops, and surveys with AMMO users to assess the application’s success in the following areas: improvements to daily operations, support of maintenance and business processes, and improvements to reporting. We compiled the feedback and provided MDOT with a report and a plan for implementing the highest-priority recommendations. In addition, DMG provided the Mississippi DOT with change management support during the implementation of recommendations, and reviewed and updated the 2006 MMS Cost-Benefit Analysis.

The Results

MDOT’s AMMO program and associated business processes has provided the agency with the following:

-State-of-the-art highway asset condition assessment process, based on a statistically significant sampling methodology, that allows monitoring of trends in asset conditions

-Level-of-Service (LOS) rating system that shows average asset conditions, by district and road class, with both technical measures and non-technical letter grades

-Performance-based budgeting process that calculates the cost of advancing from the current asset LOS ratings to desired LOS targets

-Rational basis for supporting budget requests, showing the relationships between LOS and costs, as well as the impacts of receiving less-than-requested budget amounts

-Rational bases for allocating resources to districts based on asset conditions Means for clearly communicating asset conditions and budget needs to decision makers and the public.

Mississippi Department of Transportation: Maintenance Management Consulting Services

The Client

The Mississippi DOT (MDOT) is responsible for providing a safe intermodal transportation network that is

planned, designed, constructed and maintained in an effective, cost efficient, and environmentally sensitive manner. In particular, MDOT’s Maintenance Division administers the varied programs necessary for the preservation, maintenance and safety of approximately 10,000 miles of state and federal highways.

The Challenge

In the mid-2000s, MDOT managed its maintenance and operations (M&O) needs with a legacy management system based on pass-fail ratings. MDOT wanted a more performance-based maintenance management approach that would allow it to spend time and money on the right things at the right time for the right reasons.

The Solution

Dye Management Group helped the Mississippi DOT review its maintenance business practices and processes, and prepare a plan for implementing a level-of-service (LOS)-based condition rating system and an associated condition-based activity budgeting process. The plan, along with other recommended improvements, defined the DOT’s future, or to-be, maintenance management business processes. Our team updated MDOT’s Maintenance Field Operations Manual to reflect the new, department-approved, performance-based business practices and processes. In addition, we prepared requirements and an implementation strategy for a new maintenance management system (MMS) that would enable and support the to-be maintenance business processes.

Through follow-on work, we assisted in the implementation of a newly developed maintenance quality assurance (MQA) program, performed customer surveys, and led focus groups. Our team also assisted with the procurement and implementation of a new MMS – called Accountability in MDOT Maintenance Operations (AMMO) – based on newly developed requirements, and provided project management support and organizational change management.

Most recently, DMG assisted the Mississippi DOT with a post-implementation review of the AMMO application. We conducted a series of group interviews, workshops, and surveys with AMMO users to assess the application’s success in the following areas: improvements to daily operations, support of maintenance and business processes, and improvements to reporting. We compiled the feedback and provided MDOT with a report and a plan for implementing the highest-priority recommendations. In addition, DMG provided the Mississippi DOT with change management support during the implementation of recommendations, and reviewed and updated the 2006 MMS Cost-Benefit Analysis.

The Results

MDOT’s AMMO program and associated business processes has provided the agency with the following:

- State-of-the-art highway asset condition assessment process, based on a statistically significant sampling methodology, that allows monitoring of trends in asset conditions

- Level-of-Service (LOS) rating system that shows average asset conditions, by district and road class, with both technical measures and non-technical letter grades

- Performance-based budgeting process that calculates the cost of advancing from the current asset LOS ratings to desired LOS targets

- Rational basis for supporting budget requests, showing the relationships between LOS and costs, as well as the impacts of receiving less-than-requested budget amounts

- Rational bases for allocating resources to districts based on asset conditions Means for clearly communicating asset conditions and budget needs to decision makers and the public.

Alaska Department of Transportation & Public Facilities: Long-Range Transportation Plan

The Client

The Alaska Department of Transportation and Public Facilities (DOT&PF) is responsible for a modern, efficient, and reliable statewide transportation system. Alaska is a geographically and demographically diverse state in which citizens truly travel by all modes of transportation: road, water, air, and rail.

The Challenge

The long-range plan is one element of a federally required continuing, cooperative, and comprehensive

statewide transportation planning process. The intent of the process is to guide decision making with careful planning and sound evaluation. To do so, Alaska is required to prepare a twenty-year long-range plan for all modes of transportation that addresses eight planning factors that are to be considered in all elements of the planning process. Alaska’s plan is called Let’s Get Moving 2030.

The Analysis

Let’s Get Moving 2030 provided a comprehensive analysis of Alaska’s baseline and future needs for all modes of transportation. A key objective of the analysis was to evaluate the various types of needs that the Alaska DOT&PF had to address for transportation facilities and services. The technical analysis provided a comprehensive, fact-based assessment that aided in setting priorities and planning for the future and presented a sound foundation for ongoing policy development. The models and decision support framework allowed for monitoring the performance of the transportation system and determining how to allocate funds to best meet desired outcomes.

DMG’s technical work involved:

-Conducting a baseline assessment of the state-owned transportation system. The analysis addressed the surface, marine, and air transportation facilities that the Alaska DOT&PF is responsible for and assessed the current use, condition, and performance of different elements of the system. Broad categories of need were addressed, including system development, life cycle management, and routine maintenance and operations.

-Analyzing the trends affecting the future performance of the transportation system. The analysis considered factors that would impact the future performance of the transportation system, including economic and population growth, which determines future travel demands; the level of system preservation and maintenance investment, which impacts the physical condition of the transportation system; and factors affecting the delivery of transportation solutions, such as their cost, technology transfer and innovation, and changing citizen values and priorities.

-Evaluating the ability to fund the plan. We developed a historical analysis of expenditures and future forecasts of revenue available for transportation. The technical analysis provided the information necessary to ensure that policy and plan strategies were realistic and addressed Alaska’s most pressing challenges. The information provided for a balanced and well-considered assessment of maintenance and system-preservation needs, which are often overlooked in the desire to move forward with development.

The Results

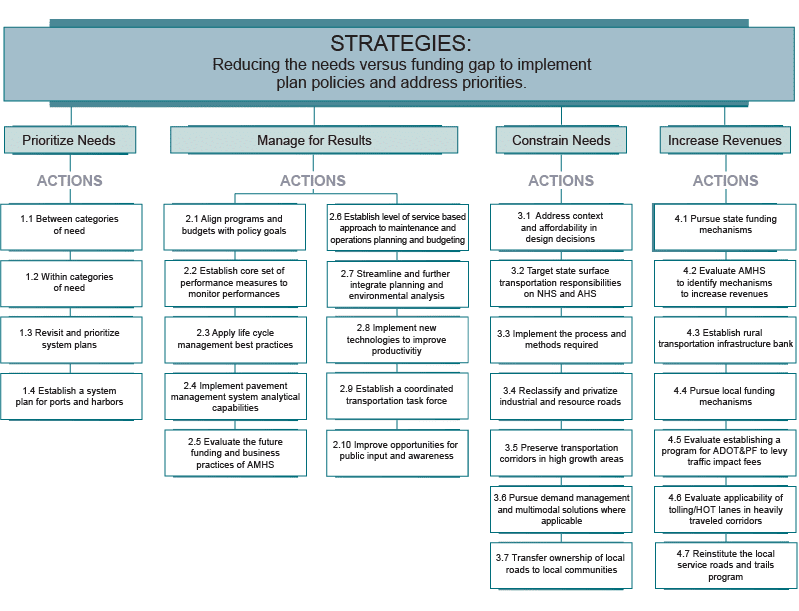

Let’s Get Moving 2030 provides state officials with goals, strategies, and actions for guiding transportation

policies, programs, and investments through 2030. This plan, detailed in the graphic below, identifies strategic priorities and provides a guide to investing transportation dollars. The Alaska DOT&PF depends on the support of all Alaska citizens to implement the Let’s Get Moving 2030 plan.

Visit the Let’s Get Moving 2030 website for more information.

Alaska Department of Transportation and Public Facilities: Long-Range Transportation Plan

The Client

The Alaska Department of Transportation and Public Facilities (DOT&PF) is responsible for a modern, efficient, and reliable statewide transportation system. Alaska is a geographically and demographically diverse state in which citizens truly travel by all modes of transportation: road, water, air, and rail.

The Challenge

The long-range plan is one element of a federally required continuing, cooperative, and comprehensive

statewide transportation planning process. The intent of the process is to guide decision making with careful planning and sound evaluation. To do so, Alaska is required to prepare a twenty-year long-range plan for all modes of transportation that addresses eight planning factors that are to be considered in all elements of the planning process. Alaska’s plan is called Let’s Get Moving 2030.

The Analysis

Let’s Get Moving 2030 provided a comprehensive analysis of Alaska’s baseline and future needs for all modes of transportation. A key objective of the analysis was to evaluate the various types of needs that the Alaska DOT&PF had to address for transportation facilities and services. The technical analysis provided a comprehensive, fact-based assessment that aided in setting priorities and planning for the future and presented a sound foundation for ongoing policy development. The models and decision support framework allowed for monitoring the performance of the transportation system and determining how to allocate funds to best meet desired outcomes.

DMG’s technical work involved:

-Conducting a baseline assessment of the state-owned transportation system. The analysis addressed the surface, marine, and air transportation facilities that the Alaska DOT&PF is responsible for and assessed the current use, condition, and performance of different elements of the system. Broad categories of need were addressed, including system development, life cycle management, and routine maintenance and operations.

-Analyzing the trends affecting the future performance of the transportation system. The analysis considered factors that would impact the future performance of the transportation system, including economic and population growth, which determines future travel demands; the level of system preservation and maintenance investment, which impacts the physical condition of the transportation system; and factors affecting the delivery of transportation solutions, such as their cost, technology transfer and innovation, and changing citizen values and priorities.

-Evaluating the ability to fund the plan. We developed a historical analysis of expenditures and future forecasts of revenue available for transportation. The technical analysis provided the information necessary to ensure that policy and plan strategies were realistic and addressed Alaska’s most pressing challenges. The information provided for a balanced and well-considered assessment of maintenance and system-preservation needs, which are often overlooked in the desire to move forward with development.

The Results

Let’s Get Moving 2030 provides state officials with goals, strategies, and actions for guiding transportation

policies, programs, and investments through 2030. This plan, detailed in the graphic below, identifies strategic priorities and provides a guide to investing transportation dollars. The Alaska DOT&PF depends on the support of all Alaska citizens to implement the Let’s Get Moving 2030 plan.

Visit the Let’s Get Moving 2030 website for more information.